Purpose

V-Groove Milling Cutters are indispensable tools for creating V-shaped grooves on workpiece surfaces. Their versatile applications span across various industries:

- Machinery Manufacturing: Utilized for processing shaft parts, connectors, and other components requiring V-grooves.

- Automobile Manufacturing: Employed in processing V-grooves on engine parts, transmission parts, and other automotive components.

- Aerospace: Crucial in precision machining of aircraft, rocket, and other aerospace vehicle components.

- Electronic Manufacturing: Essential in PCB board manufacturing for grooving, cutting, and other operations necessary for electronic product manufacturing.

-

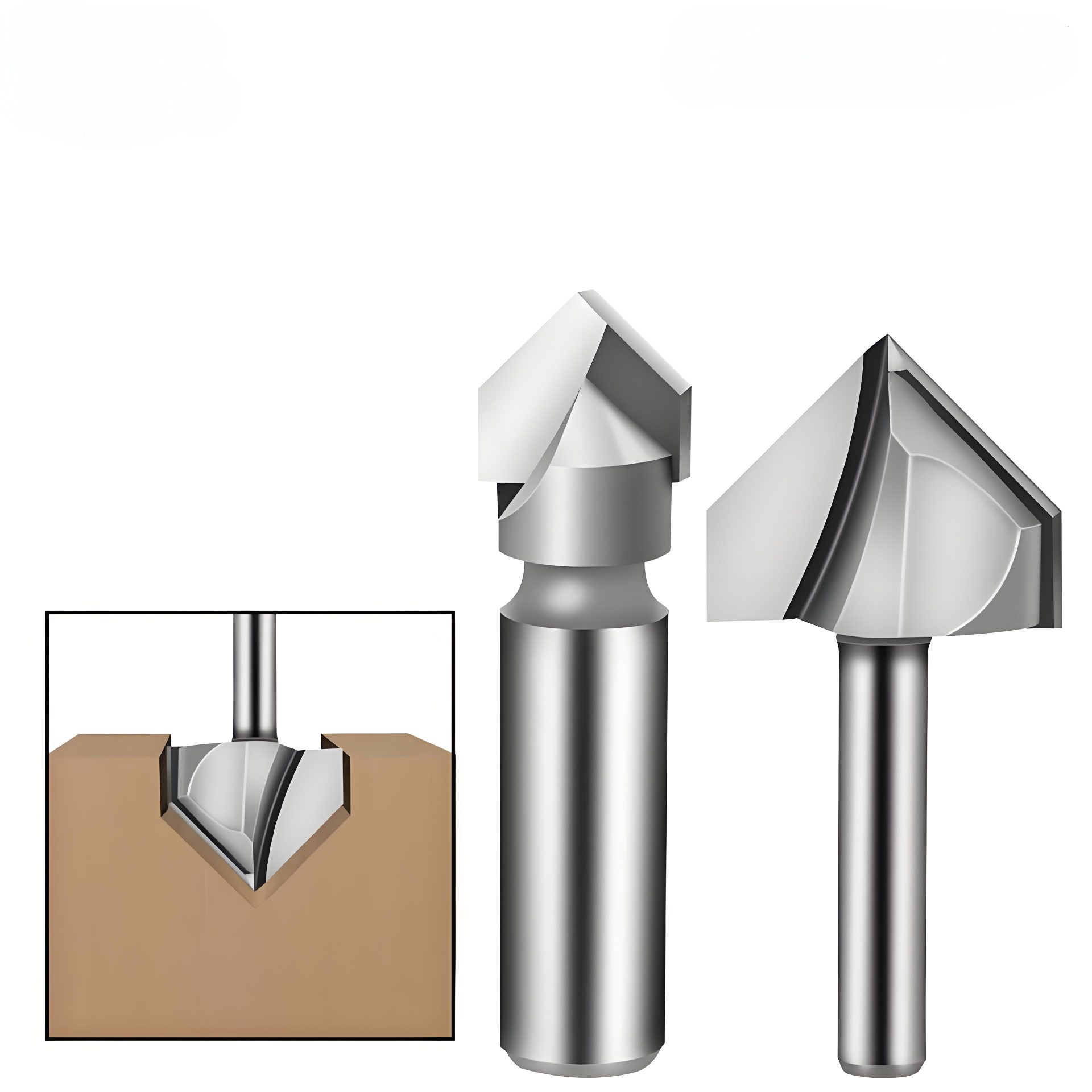

V-Groove Milling Cutters

Characteristics

V-Groove Milling Cutters boast several standout features that enhance their performance and reliability:

- Efficient Cutting: Features an optimized geometric angle design to reduce cutting force and noise, improving cutting parameters for higher production efficiency.

- High Precision: Offers high installation and processing accuracy, ensuring V-grooves of precise size and consistent shape.

- High Strength: Made from special cutter body materials, providing sufficient strength and resistance to deformation under heavy cutting forces and impacts.

- Good Versatility: Applicable to a variety of materials and processing conditions, demonstrating broad applicability.

- High Reliability: The blade positioning technology ensures the blade remains secure and undamaged during the cutting process, enhancing processing reliability and stability.

Additional Features

- Variety of Blade Specifications: Available in various blade specifications and cutting edge options to accommodate diverse processing needs.

- Good Surface Roughness: Suitable for all types of materials, with built-in wiper edges for achieving excellent surface finish.

- Flexible Cooling: Options include fixed insert seats with central cooling channels or adjustable insert seats for maximum flexibility.

V-Groove Milling Cutters are the go-to tools for precision and efficiency in V-groove machining, catering to the demands of modern manufacturing across multiple sectors.