1. Sharp blade, durable and wear-resistant, smooth cutting

2. Made of carbide and tungsten steel materials

3. The blade is sharper and shock-resistant, and the processing is more wear-resistant and durable. It is not easy to chip and break chips smoothly. It is specially designed to process stainless steel and other materials.

4. High-precision blades can effectively reduce friction and reduce losses.

5. Double-sided sharpness, hexagonal angle available, different R angles to meet your finishing and rough turning needs, reducing cutting resistance to achieve sharp cutting

| Specification | Model | Processing materials | Coating | Benchmarking products |

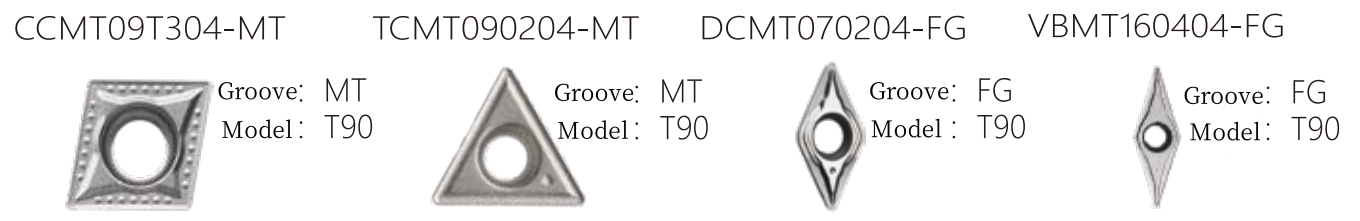

| CCMT060204-MT | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| CCMTO9T304-MT | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| TCMTO90204-MT | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| TCMT110204-MT | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| SCMTO9T304-MT | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| DCMT070204-FG | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| DCMT11T304-FG | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

| VBMT160404-FG | T90 | Semi-finishing and finishing of steel parts | bright | Japanese metal ceramics |

FAQ:

1. Flank Wear: (This is a common form of wear.)

Impact: The workpiece dimensions gradually change or the surface finish deteriorates.

Cause: The cutting speed is too high, reaching the end of the tool's service life.

Measures: Adjust the machining parameters, such as reducing the cutting speed and using more wear-resistant inserts.

2. Chipping Issue: (An undesirable form of wear.)

Impact: Sudden changes in workpiece dimensions or surface finish, resulting in a spark-strewn surface with burrs.

Cause: Inappropriate parameter settings, incorrect choice of insert material, poor workpiece rigidity, or unstable insert clamping.

Measures: Check if the parameter settings are reasonable and select the appropriate cutting tools based on the workpiece material.

3. Severe Fracture: (A very undesirable form of wear.)

Impact: Occurs suddenly and unpredictably, leading to the scrap of the tool holder, workpiece, or both.

Cause: Incorrect machining parameter settings, vibration during cutting, or the workpiece or insert not properly installed.

Measures: Set reasonable machining parameters, reduce the feed rate, choose the right cutting inserts, and enhance the rigidity of the workpiece and inserts.

4. Built-up Edge (BUE):

Impact: Inconsistent workpiece dimensions, poor surface finish, and the presence of fuzz or burrs on the workpiece surface.

Cause: Low cutting speed, low feed rate, or the insert not sharp enough.

Measures: Increase the cutting speed, adjust the feed rate, and use sharper inserts.

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us