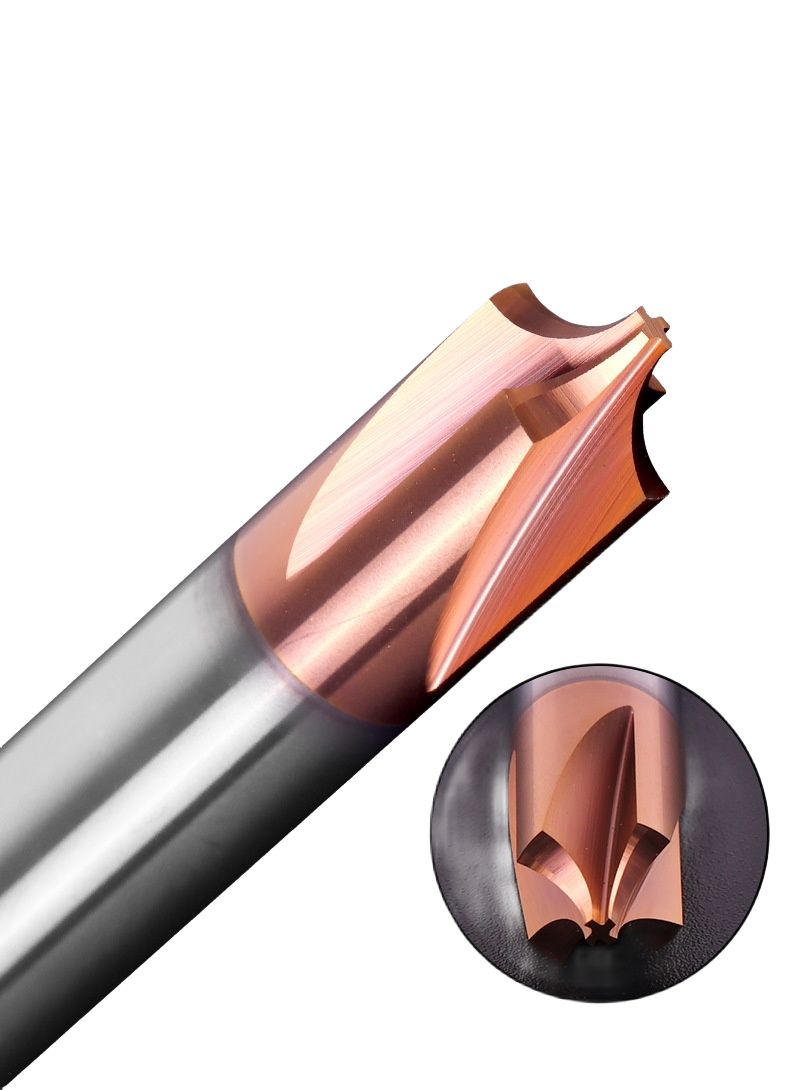

1.Material: solid carbide/tungsten steel

2. Coating: DLC colorful/nano bronze

3. Processing: copper/aluminum/steel parts/alloy steel/cast iron, etc.

4. Applicable machine tools: CNC, machining center, engraving machine and other high-end CNC milling machines

5.HRC: 56°

6.Flute: 4

Specific specifications are as follows, non-standard customization is also available:

| Specification | |

| RO.2*D3.8*D4*50L*4F | R2.0*D2*D6*50L*4F |

| R0.3*D3.4*D4*50L*4F | R2.0*D4*D8*60L*4F |

| R0.4*D3.2*D4*50L*4F | R2.5*D3*D8*60L*4F |

| RO.5*D3.0*D4*50L*4F | R3.0*D2*D8*60L*4F |

| R0.6*D2.8*D4*50L*4F | R3.0*D4*D10*60L*4F |

| R0.7*D2.6*D4*50L*4F | R3.5*D3*D10*60L*4F |

| R0.75*D2.5*D4*50L*4F | R4.0*D2*D10*60L*4F |

| R0.8*D2.4*D4*50L*4F | R4.5*D3*D12*60L*4F |

| R1.0*D2*D4*50L*4F | R5.0*D2*D12*60L*4F |

| R1.0*D4*D6*50L*4F | R5.5*D3*D14*70L*4F |

| R1.5*D3*D6*50L*4F | R6.0*D4*D16*70L*4F |

| R8.0*D4*D20*70L*4F | |

Features:

1. Use imported micro-particle tungsten steel base material, which has higher wear resistance and strength. It is an exclusive milling cutter for high hardness and high-speed cutting applications.

2. Full-edge anti-seismic design suppresses chatter during processing and improves surface quality.

3. Large core diameter is more stable, and the large core diameter design is adopted to ensure the cutting space, which greatly enhances the tool rigidity and shock resistance and reduces tool breakage.

4. The groove is processed by an ultra-fine grain grinding wheel, and the unique shape of the chip groove prevents the occurrence of built-up edges.

5. The handle is chamfered to stabilize the cutting process and help prevent tool collapse.

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us