| Material | Tungsten steel/carbide |

| Whether to support customization | YES |

| OEM & ODM | OK |

| Suitable for | aluminum or steel |

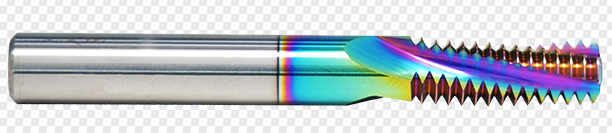

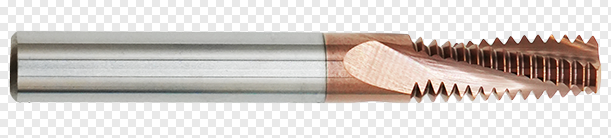

| used for | coating | picture |

| aluminum | Colorful |  |

| steel | Nano bronze |  |

Metric full teeth thread end mill specification table:

| Thread | Pitch | size | Chip flute | Recommended bottom hole | |||

| ISO standard flute | mm |

|

Flute Diameter(mm) | Flute Length(mm) | Overall Length(mm) | Z | mm |

| M3*0 . 5 | 0.5 | 4 | 2.4 | 6 | 50 | 3 | 2.5 |

| M4*0 . 5 - M5*0 . 5 | 0.5 | 4 | 3.2 | 8 | 50 | 3 | 3.5 |

| M3 . 5*0 . 6 | 0.6 | 4 | 2.8 | 7 | 50 | 3 | 2.9 |

| M4*0 . 7 | 0.7 | 4 | 3 . 15 | 8 . 4 | 50 | 3 | 3.3 |

| M6*0 .75 | 0 . 75 | 4 | 3.9 | 12 | 50 | 3 | 5.3 |

| M8*0 .75 | 0 . 75 | 6 | 5.9 | 16 | 57 | 3 | 7.3 |

| M5*0 . 8 | 0.8 | 4 | 3.9 | 10 .4 | 50 | 3 | 4 . 2 |

| M6*1 . 0 | 1 | 6 | 4.8 | 12 | 57 | 3 | 5 |

| M8*1 . 0 | 1 | 6 | 5.9 | 16 | 57 | 3 | 7 |

| M10*1 . 0 | 1 | 8 | 7.9 | 20 | 65 | 3 | 9 |

| M12*1 . 0 | 1 | 10 | 9.9 | 24 | 70 | 4 | 11 |

| M8*1 . 25 | 1 . 25 | 6 | 5.9 | 16 . 2 | 57 | 3 | 6.8 |

| M10*1 . 25 | 1 . 25 | 8 | 7.9 | 20 | 65 | 3 | 8.8 |

| M10*1 . 5 | 1.5 | 8 | 7.9 | 19 . 5 | 65 | 3 | 8.5 |

| M12*1 . 25 | 1 . 25 | 10 | 9.9 | 24 | 70 | 3 | 10 . 8 |

| M12*1 . 5 | 1.5 | 10 | 9.9 | 24 | 70 | 4 | 10 . 5 |

| M14*1 . 5 - M16*1 . 5 | 1.5 | 12 | 11 . 9 | 30 | 75 | 4 | 12 . 5 |

| M12*1 . 75 | 1 . 75 | 10 | 9.9 | 25 | 70 | 4 | 10 . 2 |

| M14*2 . 0 -M16*2 . 0 | 2 | 12 | 11.6 | 30 | 75 | 4 | 12 |

| M18*2 . 5 -M22*2 . 5 | 2.5 | 14 | 13 . 9 | 40 | 90 | 4 | 15 . 5 |

| M24*3 . 0 | 3 | 16 | 15 . 9 | 42 | 100 | 4 | 21 |

Features:

1. Fully ground cutting edge for sharp cutting

Focus on milling, effectively improve the seismic strength, wear resistance and durability, effectively guarantee the service life of the milling cutter, and have a longer service life

2. Large core diameter reduces tool breakage

The large core diameter design greatly enhances the tool rigidity and shock resistance, making cutting more stable and reducing tool breakage.

3. Large chip removal volume spiral groove

The extremely fine high-temperature-resistant coating is not afraid of high-speed milling, and chip removal is smoother. The precision-ground spiral groove avoids tool sticking and greatly improves production efficiency.

4. Universal chamfered round handle design

Easy to install and disassemble, has good compatibility, enhances the shock resistance and cutting speed of the milling cutter, holds tighter without slipping, and enhances tool stability

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us