1. Material: Carbide, imported tungsten steel, sharp and wear-resistant, sturdy and durable

2. Support other size customization

3.HRC:56°

4.Flute:3/4

5. The Flute is covered with nano-coating, which can perform high-speed finishing on stainless steel, mold steel, aluminum and other materials below 56° (including 56°), reducing the number of tool changes and improving efficiency.

6. Applicable machine tools: CNC machining center, CNC machine tool engraving machine, precision engraving machine, high-speed machine, etc.

3Flute for aluminum:

4Flute for steel:

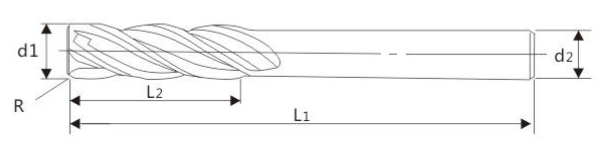

Specification table of 3/4Flute HRC56° Round Nose End Milling Cutter:

d1=Flute Diameter d2=Shank Diameter L1=Overall Length L2=Flute Length R=Radius

| Specifications | Flute Diameter(mm) | Flute Length(mm) | Shank Diameter(mm) | Overall Length(mm) | Radius(mm) |

| D6R0.2*15*D6*50L | 6 | 15 | 6 | 50 | 0.2 |

| D6R0.2*20*D6*75L | 6 | 20 | 6 | 75 | |

| D6R0.2*25*D6*100L | 6 | 25 | 6 | 100 | |

| D8R0.2*20*D8*60L | 8 | 20 | 8 | 60 | |

| D8R0.2*25*D8*75L | 8 | 25 | 8 | 75 | |

| D8R0.2*30*D8*100L | 8 | 30 | 8 | 100 | |

| D10R0.2*25*D10*75L | 10 | 25 | 10 | 75 | |

| D10R0.2*30*D10*100 | 10 | 30 | 10 | 100 | |

| D12R0.2*30*D12*75L | 12 | 30 | 12 | 75 | |

| D12R0.2*35*D12*100 | 12 | 35 | 12 | 100 | |

| D6R0.3*15*D6*50L | 6 | 15 | 6 | 50 | 0.3 |

| D6R0.5*40*D6*150L | 6 | 40 | 6 | 150 | 0.5 |

| D8R0.5*45*D8*150L | 8 | 45 | 8 | 150 | |

| D10R0.5*50*D10*150L | 10 | 50 | 10 | 150 | |

| D12R0.5*55*D12*150L | 12 | 55 | 12 | 150 | |

| D16R0.5*45*D16*100L | 16 | 45 | 16 | 100 | |

| D16R0.5*75*D16*150L | 16 | 75 | 16 | 150 | |

| D20R0.5*45*D20*100L | 20 | 45 | 20 | 100 | |

| D20R0.5*75*D20*150L | 20 | 75 | 20 | 150 | |

| D6R0.5*40*D6*150L | 6 | 40 | 6 | 150 | |

| D8R1*45*D8*150L | 8 | 45 | 8 | 150 | 1 |

| D10R1*50*D10*150L | 10 | 50 | 10 | 150 | |

| D12R1*55*D12*150L | 12 | 55 | 12 | 150 | |

| D16R1*75*D16*150L | 16 | 75 | 16 | 150 | |

| D20R1*75*D20*150L | 20 | 75 | 20 | 150 | |

| D6.5R1.5*15*D6*50L | 6.5 | 15 | 6 | 50 | 1.5 |

| D8.5R1.5*20*D8*60L | 8.5 | 20 | 8 | 60 | |

| D10.5R1.5*25*D10*75L | 10.5 | 25 | 10 | 75 | |

| D12.5R1.5*30*D12*75L | 12.5 | 30 | 12 | 75 | |

| D8R2*20*D8*60L | 8 | 20 | 8 | 60 | 2 |

| D8R2*30*D8*100l | 8 | 30 | 8 | 100 | |

| D10R2*25*D10*75L | 10 | 25 | 10 | 75 | |

| D10R2*30*D10*100L | 10 | 30 | 10 | 100 | |

| D12R2*30*D12*75L | 12 | 30 | 12 | 75 | |

| D12R2*35*D12*100l | 12 | 35 | 12 | 100 | |

| D16R2*45*D16*100L | 16 | 45 | 16 | 100 | |

| D10R3*25*D10*75L | 10 | 25 | 10 | 75 | 3 |

| D10R3*30*D10*100L | 10 | 30 | 10 | 100 | |

| D12R3*30*D12*75L | 12 | 30 | 12 | 75 | |

| D12R3*35*D12*100L | 12 | 35 | 12 | 100 | |

| D16R3*45*D16*100L | 16 | 45 | 16 | 100 |

1. Origin of the Name

The most distinctive feature of the ball nose end mill is its tip part, which presents a round arc shape, resembling the shape of a nose, hence the name "ball nose." This round arc design allows the tool to cut materials smoothly during the machining process, particularly when performing three-dimensional curved surface processing, resulting in a high-quality surface finish.

2. Product Features

① Dual round arc and helix angle design make the end mill more wear-resistant; during processing, it reduces product burrs and enhances surface smoothness.

② The adoption of a suitable negative rake angle design balances the strength and sharpness of the cutting edge. Additionally, a large core diameter is used to enhance the tool rigidity, ensuring stable cutting and chip evacuation.

③ Large chip evacuation space: The larger capacity chip slot provides powerful cutting and smooth chip discharge. This achieves high-efficiency machining with higher precision and a more lustrous finish on the workpiece.

④ Easy chamfering operation: The chamfered layout at the shank part makes clamping easier, with a smooth and bright chamfer. The craftsmanship is outstanding, creating a rounded, solid, and aesthetically pleasing application.

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us