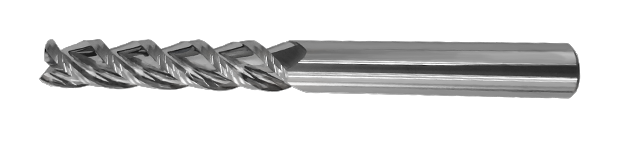

1.Material:Tungsten steel/carbide

2. Customizable

3.Hrc: 56°

4.Flute: 3

5. Coating: Nano coating

6. Large chip removal capacity, fully ground spiral groove

7. Compatible with edge strength and sharpness, enhancing tool rigidity and burr-free edge, reducing the number of tool changes and extending service life.

Notice:

1. Long flute end mill has a longer protrusion and is more susceptible to vibration and deflection, so special attention needs to be paid to stability when clamping. When using, make sure the connection between the milling cutter and the tool holder is firm to avoid loosening or falling of the milling cutter during processing.

2. When long flute end mill must be used, the cutting speed and feed speed should be significantly reduced to reduce vibration and improve tool life.

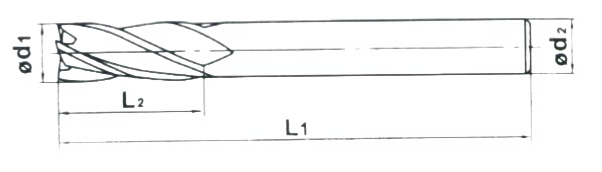

| d1 | L2 | d2 | L1 | |

| Specifications | Flute Diameter(mm) | Flute Length(mm) | Shank Diameter(mm) | Overall Length(mm) |

| D6*45*120L | 6 | 45 | 6 | 120 |

| D8*50*120L | 8 | 50 | 8 | 120 |

| D10*60*120L | 10 | 60 | 10 | 120 |

| D12*60*120L | 12 | 60 | 12 | 120 |

| D8*70*200L | 8 | 70 | 8 | 200 |

| D10*80*200L | 10 | 80 | 10 | 200 |

| D12*80*200L | 12 | 80 | 12 | 200 |

| D14*100*200L | 14 | 100 | 14 | 200 |

| D16*100*200L | 16 | 100 | 16 | 200 |

| D20*100*200L | 20 | 100 | 20 | 200 |

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us