| Material | Tungsten steel/carbide |

| Whether to support customization | YES |

| Hrc | 55°/56°/58° |

| Flute | 3 |

| OEM & ODM | OK |

| Suitable for | aluminum |

3Flute milling cutter is a commonly used machine tool tool, mainly used for processing various grooves and step surfaces. This milling cutter is characterized by teeth on both sides and circumference, allowing it to cut in different directions.Coatings include DLC colorful, mirror reflection, High gloss without vibration, Flute Diameter ranging from 1mm to 20mm, and other specifications can also be customized.

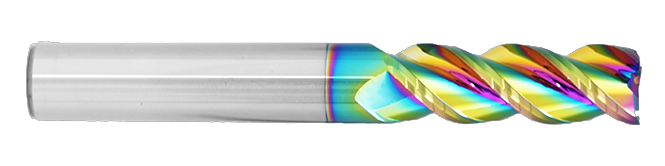

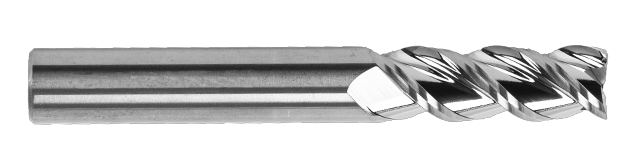

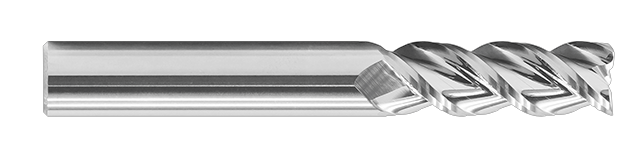

| HRC | Coating | picture |

| 55° | DLC colorful |  |

| 55° | mirror reflection |  |

| 56° | mirror reflection |  |

| 58° | High gloss without vibration |  |

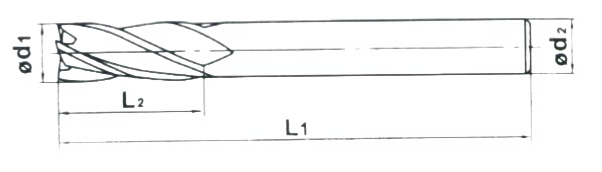

| d1 | L2 | d2 | L1 | |

| Specifications | Flute Diameter(mm) | Flute Length(mm) | Shank Diameter(mm) | Overall Length(mm) |

| D1*3*D4*50L*3F | 1 | 3 | 4 | 50 |

| D1.5*4.5*D4*50L*3F | 1.5 | 4.5 | 4 | 50 |

| D2*6*D4*50L*3F | 2 | 6 | 4 | 50 |

| D2.5*7.5*D4*50L*3F | 2.5 | 7.5 | 4 | 50 |

| D3*9*D4*50L*3F | 3 | 9 | 4 | 50 |

| D3*9*D3*50L*3F | 3 | 9 | 3 | 50 |

| D3*12*D3*75L*3F | 3 | 12 | 3 | 75 |

| D3*15*D3*100L*3F | 3 | 15 | 3 | 100 |

| D3.5*10*D4*50L*3F | 3.5 | 10 | 4 | 50 |

| D4*12*D4*50L*3F | 4 | 12 | 4 | 50 |

| D4*16*D4*75L*3F | 4 | 16 | 4 | 75 |

| D4*20*D4*100L*3F | 4 | 20 | 4 | 100 |

| D5*15*D6*50L*3F | 5 | 15 | 6 | 50 |

| D5*15*D5*50L*3F | 5 | 15 | 5 | 50 |

| D5*20*D5*75L*3F | 5 | 20 | 5 | 75 |

| D5*25*D5*100L*3F | 5 | 25 | 7 | 100 |

| D6*18*D6*50L*3F | 6 | 18 | 6 | 50 |

| D6*24*D6*75L*3F | 6 | 24 | 6 | 75 |

| D6*30*D6*100L*3F | 6 | 30 | 6 | 100 |

| D8*24*D8*60L*3F | 8 | 30 | 8 | 60 |

| D8*30*D8*75L*3F | 8 | 30 | 8 | 75 |

| D8*35*D8*100L*3F | 8 | 35 | 8 | 100 |

| D10*30*D10*75L*3F | 10 | 30 | 10 | 75 |

| D10*45*D10*100L*3F | 10 | 45 | 10 | 100 |

| D12*35*D12*75L*3F | 12 | 35 | 12 | 75 |

| D12*45*D12*100L*3F | 12 | 45 | 12 | 100 |

| D14*45*D14*100L*3F | 14 | 45 | 14 | 100 |

| D16*45*D16*100L*3F | 16 | 45 | 16 | 100 |

| D18*45*D18*100L*3F | 18 | 45 | 18 | 100 |

| D20*45*D20*100L*3F | 20 | 45 | 20 | 100 |

| D6*45*D6*150L*3F | 6 | 45 | 6 | 150 |

| D8*50*D8*150L*3F | 8 | 50 | 8 | 150 |

| D10*60*D10*150L*3F | 10 | 60 | 10 | 150 |

| D12*60*D12*150L*3F | 12 | 60 | 12 | 150 |

| D14*70*D14*150L*3F | 14 | 70 | 14 | 150 |

| D16*75*D16*150L3F | 16 | 75 | 16 | 150 |

| D18*75*D18*150L*3F | 18 | 75 | 18 | 150 |

| D20*75*D20*150L*3F | 20 | 75 | 20 | 150 |

| D2*6*D2*50L*3F | 2 | 6 | 2 | 50 |

FAQ:

1、Why choose us?

China source manufacturers, cheap price, good quality cutter

2、What should I pay attention to when using 3-flute milling cutter?

(1) When using the tool, make sure the quality of the tool and the wear of the cutting edge, and replace the tool if necessary, so as not to affect the processing effect and quality.

(2) Before tool machining, the machine, tool and workpiece should be checked to ensure that the machining conditions and machining procedures are correct.

(3) In the use of three-sided cutting edge milling cutter for milling, should be based on specific processing requirements to choose the appropriate speed and feed rate, in order to avoid overheating and overload and other situations.

(4) When milling the workpiece with three-face edges, it is necessary to pay attention to the size of the feed and the control of the depth of cut, so as to avoid damaging the tool and the workpiece due to the excessive feed or the excessive depth of cut.

(5) When machining thin-walled or small parts, pay attention to the cutting status of the tool and the cooling of the tool to reduce the thermal deformation of the tool and workpiece as much as possible to ensure the machining effect and accuracy.

3、How to judge the milling cutter passivation

(1) From the shape of the chip, the chip becomes coarse, flaky, and the chip colour is purple and smoky;

(2) The roughness of the surface of the workpiece processing is very poor, the surface of the workpiece appears bright, there are traces of gnawing or ripples;

(3) The milling process produces serious vibration and abnormal noise;

(4) There are bright white spots on the cutter;

(5) When milling steel parts with carbide milling cutter, a lot of fire mist often flies out;

(6) When milling steel parts with high-speed steel milling cutters, a large amount of smoke is produced.

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us