1.Made of solid carbide material, wear-resistant and durable, with good smoothness

2.DLC coating & nano black coating, harder, not easy to wear and long service life

3.A variety of specifications are available and can also be customized

4.There are cutting edges at the top and bottom of the angle, which can meet the requirements of upper and lower positive and negative chamfering. In addition, with the extra long space, it can also meet the needs of deep hole processing.

5. The cutter head adopts a double-edged blade with a core. The cutting edge is finely ground, sharp, wear-resistant and not easy to collapse, making the processing more lustrous.

6.HRC56, suitable for cast iron, carbon steel, copper, stainless steel, alloy steel, spring steel\aluminum, aluminum alloy, magnesium alloy, zinc alloy and other materials

7.Large chip flute design, large chip space, can make chip removal smoother and effectively solve problems such as tool sticking, chipping and improve production efficiency.

8.Reasonable air avoidance design has a wider chip removal space, which is conducive to reducing chip removal resistance and improving the surface finish of the workpiece.

9.Passivation treatment and smooth edge

10.Applicable machines: CNC, engraving machine, precision engraving machine

The Chamfer End Mills is a tool that is installed on milling machines, drilling machines, planers, chamfering machines and other machine tools for processing workpieces with 60 degrees, 82 degrees, 90 degrees, 100 degrees, 110 degrees and 120 degrees chamfering, tapered holes, and corners. , belongs to end mill。

| Picture | Coating | Used for |

|

DLC colorful | aluminum |

|

Nano black | steel |

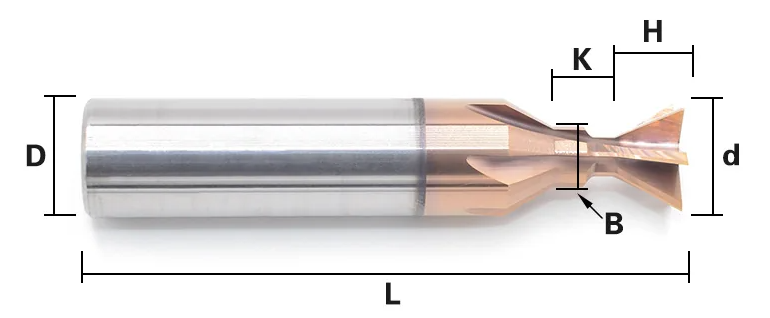

The specific models are as shown in the table below, and customization is also available.

Angle

|

Specification |

| 60° | d*60°*0.64H*B0.9*3K*D4*50L |

| d*60°*0.92H*B1.4*4K*D4*50L | |

| d*60°*1.24H*B1.9*8K*D4*50L | |

| d*60°*1.56H*B2.3*10K*D6*50L | |

| d*60°*1.9H*B2.8*10K*D6*50L | |

| d*60°*2.54H*B3.6*12K*D8*60L | |

| d*60°*3.18H*B4.5*15K*D10*60L | |

| d*60°*3.81H*B5.4*18K*D12*60L | |

| 90° | d*90°*1.1H*B0.9*3K*D4*50L |

| d*90°*1.6H*B1.4*4K*D4*50L | |

| d*90°*2.15H*B1.9*8K*D4*50L | |

| d*90°*2.7H*B2.3*10K*D6*50L | |

| d*90°*3.3H*B2.8*10K*D6*50L | |

| d*90°*4.4H*B3.6*12K*D8*60L | |

| d*90°*5.5H*B4.5*15K*D10*60L | |

| d*90°*6.6H*B5.4*18K*D12*60L | |

| 120° | d*120°*1.9H*B0.9*3K*D4*50L |

| d*120°*2.77H*B1.4*4K*D4*50L | |

| d*120°*3.72H*B1.9*8K*D4*50L | |

| d*120°*4.67H*B2.3*10K*D6*50L | |

| d*120°*5.71H*B2.8*10K*D6*50L | |

| d*120°*7.62H*B3.6*12K*D8*60L | |

| d*120**9.53H*B4.5*15K*D10*60L | |

| d*120°*11.43H*B5.4*18K*D12*60L |

Characteristics of DLC coating and nano black coating

1. DLC coating, namely Diamond-Like Carbon coatings, is an amorphous carbon material whose structure contains sp3, sp2 and sp1 bonds in different proportions. This coating has been widely used in many fields due to its unique properties. Here are some of the key features of DLC coatings:

High hardness and excellent wear resistance: The hardness of DLC coating can reach 20% of natural diamond, making it an ideal hard tool coating. This high hardness makes DLC coatings ideal for increasing the life and efficiency of tools such as bearings and cutting tools.

Low coefficient of friction: DLC coating has a low coefficient of friction, which helps reduce friction and wear during mechanical movement, thereby extending the service life of the equipment.

Good chemical stability: DLC coatings exhibit good chemical inertness and are resistant to a wide range of chemicals, including acids, bases and salts.

2. Nano black coating usually has high hardness and excellent wear resistance, which can effectively resist wear during cutting and extend the service life of milling cutters.

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us