Material: Tungsten steel/carbide

Hrc: 55°/58°/60°/62°/65°

Applicable to: steel, aluminum, cast iron and other materials

Coating: TiAIN+TiSiN/TiAIN+AICrSiN/nano coating

Applicable machines: CNC machining centers, engraving machines, engraving machines and other high-speed machines

Our advantage:

① Imported coating technology, high hardness, wear-resistant and durable, high precision

②Chinese source manufacturer, guaranteed after-sales service, cheap price

③.Support various size customization services and also provide polishing services.

④ Samples can be sent

1、HRC55°4Flute milling cutter:

Use 0.8 grain WC powder and imported target material TiAIN+TiSiN composite coating to cope with the process

Poor processing conditions.

Use 0.8 grain WC powder and imported target material TiAIN+TiSiN composite coating to cope with the process

Poor processing conditions.

Suitable for semi-finishing HRC<35 steel parts, copper parts and cast iron

Use of rough machining.

2、HRC58°4Flute milling cutter:

Using 0.4 grain WC powder, 35 degree helix angle with engraved back, imported target material TiAIN+AICrSiN composite coating, all imported machine grinding, sandblasting passivation treatment, strong precision performance and stability.

3、HRC60°4Flute milling cutter:

Using 0.4 grain WC powder, 35 degree helix angle with engraved back, imported target material TiAIN+AICrSiN composite coating, all imported machine grinding, sandblasting passivation treatment, strong precision performance and stability.

3、HRC60°4Flute milling cutter:

Using 0.4 grain WC powder, 45 degree helix angle, imported target TiAISiN coating, sandblasting passivation treatment, economical alternative to blue nanometer.

Suitable for finishing, semi-finishing and roughing of HRC<48 steel parts.

4、HRC62°4Flute milling cutter:

Use 0.4 grain WC powder, 40 degree helix angle with engraved back, targeted front angle design, imported target TiAIN+AICrSiN composite coating, all imported machine grinding, sandblasting passivation treatment, strong precision performance and stability.

Suitable for finishing and semi-finishing of HRC≤55 mold steel parts and stainless steel.

5、HRC65°4Flute milling cutter:

Use 0.4 grain WC powder, 40 degree helix angle with engraved back, targeted front angle design, imported target TiAIN+AICrSiN composite coating, all imported machine grinding, sandblasting passivation treatment, strong precision performance and stability.

Suitable for finishing and semi-finishing of HRC≤55 mold steel parts and stainless steel.

5、HRC65°4Flute milling cutter:

Using 0.4 grains of WC powder with a 40-degree helix angle and an engraved back, the front angle is targeted and the imported target TiAISiN coating is all ground by imported machines and sandblasted and passivated to achieve strong accuracy, performance and stability.

Suitable for HRC<55 mold steel parts and stainless steel precision machining and semi-precision work.

Using 0.4 grains of WC powder with a 40-degree helix angle and an engraved back, the front angle is targeted and the imported target TiAISiN coating is all ground by imported machines and sandblasted and passivated to achieve strong accuracy, performance and stability.

Suitable for HRC<55 mold steel parts and stainless steel precision machining and semi-precision work.

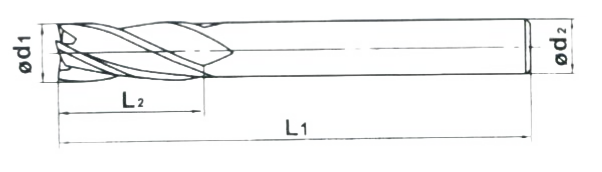

carbide 4Flute milling cutter specification table:

| d1 | L1 | d2 | L2 | |

| specifications | Flute Diameter(mm) | Flute Length(mm) | Shank Diameter(mm) | Overall Length(mm) |

| D1*3*D4*50L | 1 | 3 | 4 | 50 |

| D1.5*4.5*D4*50L | 1.5 | 4.5 | 4 | 50 |

| D2*6*D2*50L | 2 | 6 | 2 | 50 |

| D2*6*D4*50L | 2 | 6 | 4 | 50 |

| D2.5*7.5*D4*50 | 2.5 | 7.5 | 4 | 50 |

| D3*9*D4*50L | 3 | 9 | 4 | 50 |

| D3*9*D3*50L | 3 | 9 | 3 | 50 |

| D3*12*D3*75L | 3 | 12 | 3 | 75 |

| D3*15*D3*100L | 3 | 15 | 3 | 100 |

| D3.5*10*D4*50L | 3.5 | 10 | 4 | 50 |

| D4*10*D4*501 | 4 | 10 | 4 | 50 |

| D4*16*D4*75L | 4 | 16 | 4 | 75 |

| D4*20*D4*100L | 4 | 20 | 4 | 100 |

| D5*13*D6*50L | 5 | 13 | 6 | 50 |

| D5*13*D5*50L | 5 | 13 | 5 | 50 |

| D5*20*D5*75L | 5 | 20 | 5 | 75 |

| D5*25*D5*100L | 5 | 25 | 5 | 100 |

| D6*15*D6*50L | 6 | 15 | 6 | 50 |

| D6*24*D6*75L | 6 | 25 | 6 | 75 |

| D6*30*D6*100L | 6 | 30 | 6 | 100 |

| D6*45*D6*150L | 6 | 45 | 6 | 150 |

| D8*20*D8*60L | 8 | 20 | 8 | 60 |

| D8*30*D8*75L | 8 | 30 | 8 | 75 |

| D8*35*D8*100L | 8 | 35 | 8 | 100 |

| D8*50*D8*150L | 8 | 50 | 8 | 15 |

| D10*25*D10*75L | 10 | 25 | 10 | 75 |

| D10*40*D10*100L | 10 | 40 | 10 | 100 |

| D10*60*D10*150L | 10 | 60 | 10 | 150 |

| D12*30*D12*75L | 12 | 30 | 12 | 75 |

| D12*45*D12*100L | 12 | 45 | 12 | 100 |

| D12*60*D12*150L | 12 | 60 | 12 | 150 |

| D14*45*D14*100L | 14 | 45 | 14 | 100 |

| D14*70*D14*150L | 14 | 70 | 14 | 150 |

| D16*45*D16*100L | 16 | 45 | 16 | 100 |

| D16*75*D16*150L | 16 | 75 | 16 | 150 |

| D18*45*D18*100L | 18 | 45 | 18 | 100 |

| D18*75*D18*150L | 18 | 75 | 18 | 150 |

| D20*45*D20*100L | 20 | 45 | 20 | 100 |

| D20*75*D20*150L | 20 | 75 | 20 | 150 |

| D25*45*D25*100L | 25 | 45 | 25 | 100 |

Product Details:

|

|

Common coatings for milling cutters and their respective characteristics:

1. Titanium Nitride Coating (TiN)

-General purpose PVD coating, improves tool hardness and has a high oxidation temperature.

-Suitable for HSS cutting tools and shaping tools, especially excellent in machining softer metals (e.g. copper, mild steel).

-Improves tool surface hardness, reduces chemical affinity, reduces adhesion damage and improves anti-wear function.

2. Titanium Carbide Nitride Coating (TiCN)

-The addition of carbon increases tool hardness and improves surface lubrication.

-Has lower coefficient of friction and higher hardness than TiN coating.

-Suitable for milling hard materials such as stainless steel, titanium alloys and nickel alloys to improve tool life.

3. Titanium Aluminium Nitride and Titanium Aluminium Nitride Coating (TiAlN/AlTiN)

-The aluminium oxide layer formed improves tool life in high temperature machining.

-Can be used on carbide tools for dry or semi-dry cutting operations.

-AlTiN coating provides higher surface hardness than TiAlN and is suitable for high speed machining areas.

4. Chromium Nitride Coating (CrN)

-Good anti-bonding properties, suitable for machining that is prone to chip-accumulation tumours.

-Improve the machining performance of high-speed steel, carbide and other tools.

5. Diamond Coating (Diamond)

-CVD diamond coating provides excellent performance and is suitable for non-ferrous metal machining.

-Tool life is many times that of carbide tools, especially suitable for machining graphite, metal matrix composites and other high wear materials.

-Note: Pure diamond coatings are not suitable for machining steel parts to avoid chemical reactions that can damage the coating.

6. Oxide Coating (Homo)

-By heating the surface of the tool in water vapour at 500 to 550ºC, a Fe3O4 layer is generated.

-The porous oxide film retains cutting oil and reduces frictional heat.

-Suitable for hard-to-cut materials, high tensile steel, stainless steel, cast iron, etc. to reduce wear.

7、Nano-coating

Nano-coating significantly improves the hardness and wear resistance of the material by adding nanoscale particles to the conventional coating. This enhanced mechanical property makes nano coatings ideal for applications requiring high wear and scratch resistance, such as machine parts, tools and equipment surfaces

Share to

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us