Our lathe boring tools, specifically the micro-diameter MTR/MPR/MUR/MQR series, are designed for precision machining and offer several key advantages for various industrial applications.

Advantages

-

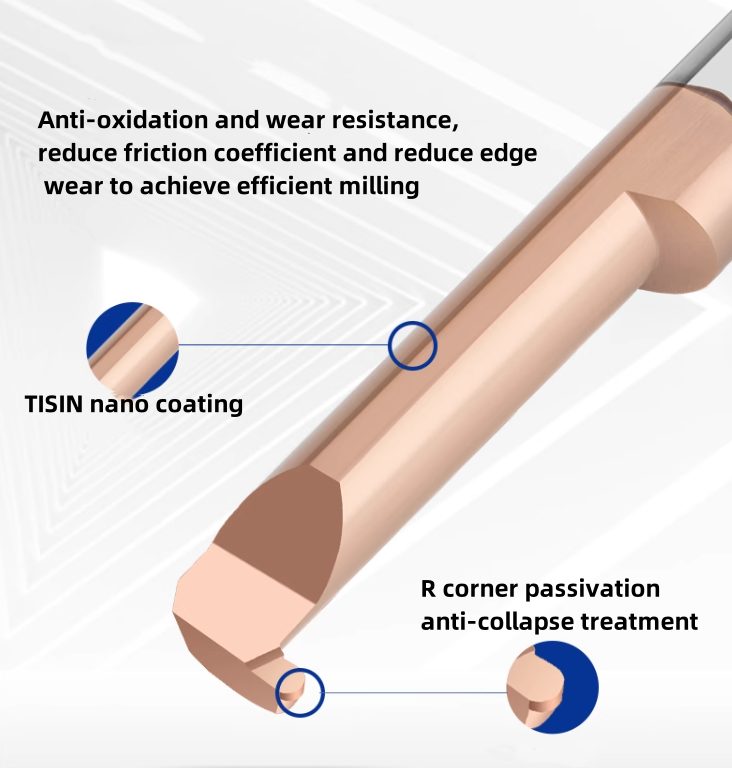

Enhanced Durability: These tools are coated with a gold nanocomposite, which significantly extends their service life and ensures high versatility. They can be used on a wide range of materials, including copper, aluminum, steel, stainless steel, and cast iron.

-

Precision Engineering: Manufactured using imported five-axis machine tools, these tools are ground through a one-piece molding process, ensuring high R-angle accuracy and sharp cutting edges. This precision guarantees superior machining quality and consistency.

-

High-Quality Material: Made from high-quality tungsten steel, these tools are wear-resistant and durable. They improve processing efficiency, reduce the frequency of tool changes, and ensure a stable machining cycle.

Applications

These lathe boring tools are ideal for precision machining in industries such as automotive, aerospace, and mechanical manufacturing. They are particularly suited for creating micro-diameter holes and complex internal geometries with high accuracy.

Notes for Use

-

Tool Selection: Choose the appropriate tool model (MTR, MPR, MUR, or MQR) based on the specific machining requirements and material properties.

-

Coolant Use: Always use a suitable coolant to prevent overheating and extend tool life.

-

Regular Maintenance: Inspect and maintain the tools regularly to ensure optimal performance and longevity.

Our lathe boring tools are designed to meet the highest standards of precision and reliability, making them an excellent choice for demanding machining tasks