Ball nose end mills are versatile tools used for machining complex geometries and achieving smooth surface finishes. However, selecting the correct feeds and speeds is crucial for optimal performance and tool life. Here are some guidelines for determining the appropriate feeds and speeds for ball nose end mills: Factors Affecting Feeds and Speeds Workpiece Material: […]

Tungsten carbide drill bits are highly effective for drilling hardened steel due to their exceptional hardness and durability. Here are the key requirements and characteristics for tungsten carbide drill bits used in such applications: Material and Composition Hardness: Tungsten carbide has a hardness value of around 1600HV, making it significantly harder than steel. This allows […]

To calculate the speeds and feeds for an end mill, you can use various online tools and formulas. Here’s a step-by-step guide to help you determine the optimal cutting parameters: 1. Determine Cutting Speed (SFM or SMM) Cutting speed is the speed at which the cutting tool moves through the material. It is typically measured in […]

Thread milling is a highly precise and versatile machining technique that has become increasingly popular in modern manufacturing processes. It involves the use of specialized thread milling cutters to create internal and external threads with exceptional accuracy and consistency. Unlike traditional tapping methods, thread milling offers numerous advantages, including enhanced thread quality, reduced tool wear, […]

To prevent alloy from rusting, you can use the following methods: Protective Coatings: Paint: Apply a layer of paint to create a barrier against moisture and oxygen. Powder Coating: A durable and even coating that provides excellent protection. Galvanizing: Coat the alloy with a layer of zinc to prevent rust. Electroplating: Chromium or Nickel Plating: […]

When transporting milling cutters, attention should be paid to protecting the cutting edges and accuracy of the tools and preventing safety accidents. The specific precautions are as follows: Packaging and Protection Select Appropriate Packaging MaterialsMilling cutters should be packaged in special tool packaging boxes or bags. Soft and cushioning materials such as foam plastics […]

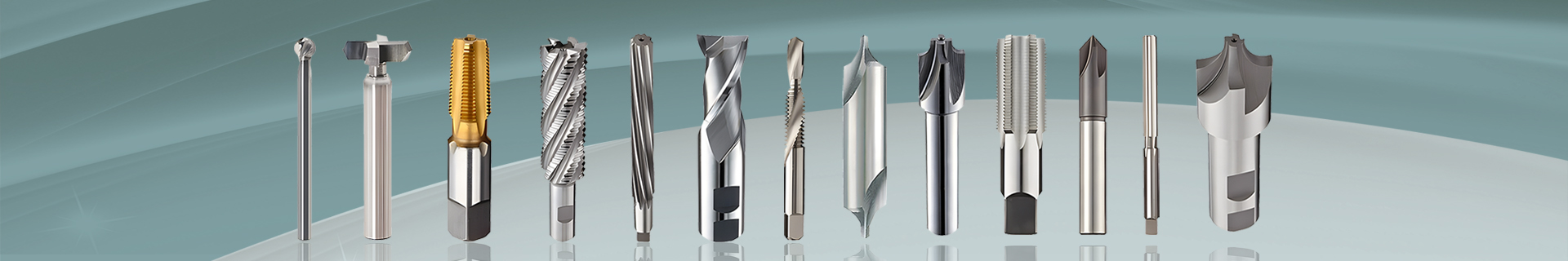

I. Common Types of Milling Cutters Carbide Milling Cutters Advantages: Due to titanium alloy's low elastic modulus, high friction between the tool's rear face and the workpiece, and high cutting temperatures, it is necessary to choose tool materials with good wear resistance and high temperature tolerance. Carbide milling cutters possess high hardness and wear resistance, […]

When processing tungsten steel, the following tools are commonly utilized due to the material's high hardness, heat resistance, and wear resistance: - Tungsten Steel Cutting Tools: - Tungsten steel (carbide) cutting tools are characterized by high hardness, good strength, and toughness, maintaining their properties even at high temperatures. They are ideal for machining tungsten steel […]

Trapezoidal thread is a commonly used thread form with an asymmetric tooth shape and is widely used in mechanical transmission and other applications requiring high load capacity. The trapezoidal thread milling cutter is one of the tools specially designed to process this special thread. This milling cutter is designed with specific angles and shapes to […]

Solving the problem of boring tool vibration often requires analysis and adjustment from multiple angles. Here are some possible solutions: 1. Improve the rigidity of the tool system: Use more rigid tool holders, boring bars and boring heads to reduce the overhang length, especially in the processing of small holes, deep holes and hard workpieces. […]

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us