As a key part of the manufacturing industry, metal processing has made significant progress in intelligence in recent years thanks to technological progress and the development of artificial intelligence. These advancements not only improve production efficiency and product quality, but also reduce costs and ensure production stability and product uniformity. The following are several key […]

1. Pour some lubricating oil, use a sharp hairpin or chopper to slowly knock out the fracture surface in the opposite direction, and occasionally turn the iron over to sharpen it (the most common method in the workshop, but for threaded holes with too small diameter or broken taps that are too large) It may […]

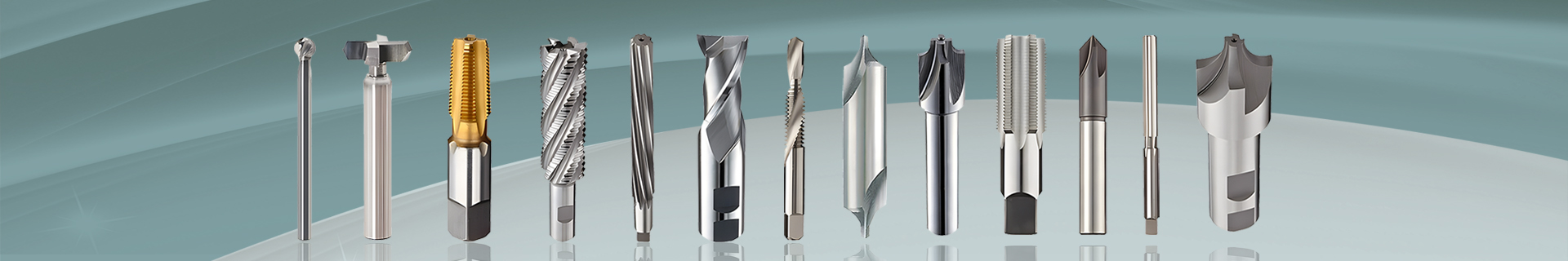

1. The most important thing in processing is the tool Any tool that stops working means production is at a standstill. But that doesn’t mean every knife has the same importance. The tool with the longest cutting time has a greater impact on the production cycle, so under the same conditions, more attention should be […]

Tungsten steel milling cutter is a tool made of tungsten steel (tungsten carbide, also known as tungsten-titanium alloy). Generally mainly used in CNC machining centers and CNC engraving machines. It can also be installed on an ordinary milling machine to process some relatively hard and uncomplicated heat treatment materials. Tungsten steel milling cutters are widely […]

(1) When sharpening each edge surface separately, use the tip of each edge as the benchmark and keep the edge as the principle, and then grind the rake angle (no need to grind if there is no chipping), the relief angle, and the secondary relief angle ( If a large cutting volume requires better strength, […]

If there is no circular groove on the front of the end face of the four-blade tungsten steel milling cutter, you need to use the fillet of the grinding wheel or use a grinding wheel cutting machine to re-open the cross groove in the direction of the cross spiral groove of the milling cutter, with […]

No matter how many blades a tungsten steel milling cutter has, the end face of the blade must first be ground flat perpendicular to the axis. This is the key to ensuring that the highest point of the blade is on the same plane. The methods for grinding the blade end face and checking the […]

Ceramic cutting tools are characterized by high hardness, excellent wear resistance, good thermal stability, and chemical stability, and they do not easily adhere to metals. They hold a very important position in CNC machining and have become one of the main cutting tools for high-speed cutting and machining of difficult-to-process materials. Ceramic tools are widely […]

High-Speed Steel (HSS), which stands for High-Speed Steel, is a high-alloy tool steel that incorporates a significant amount of alloying elements such as tungsten (W), molybdenum (Mo), chromium (Cr), and vanadium (V). HSS tools exhibit excellent comprehensive properties in terms of strength, toughness, and workability, and they still hold a dominant position in the manufacturing […]

Matching of Cutting Tool Materials with Workpiece Mechanical, Physical, and Chemical Properties for Optimal Machining Performance 1. Mechanical Property Match Between Cutting Tools and Workpieces The matching problem regarding mechanical properties primarily involves the alignment of tool materials' strength, toughness, and hardness with those of workpiece materials. Different tool materials are suitable for machining different […]

CopyRight © 2024 - Changzhou Saimo Tools Co., Ltd. All rights reserved.

WhatsApp us