1. milling plane

Plane milling uses the circumferential edge or end edge of the milling cutter to feed in a direction parallel to the workpiece plane to form a plane parallel to the feed direction of the workpiece, as shown in Figure 1-1.

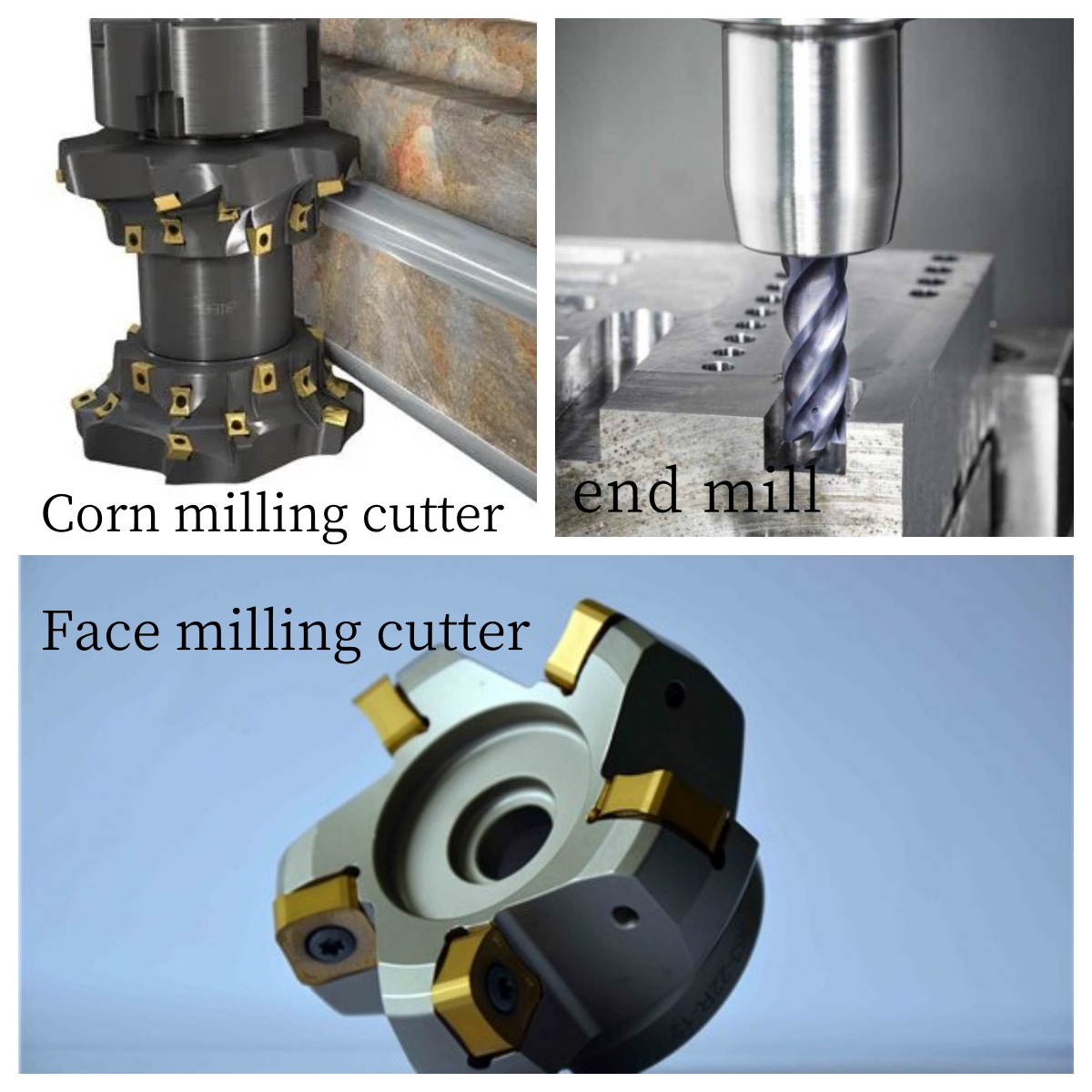

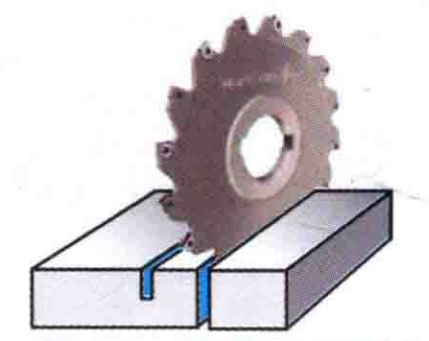

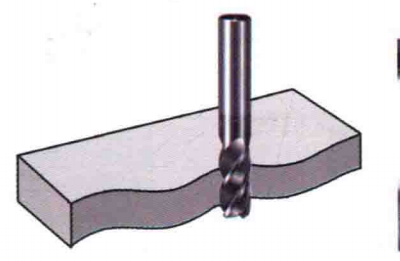

2、milling groove

Milling groove (usually refers to milling at least one section of the straight groove is not closed) is the same time with the milling cutter circumferential edge and endface edge, in the workpiece machined open or closed groove (see Figure 1-2). Closed grooves are generally machined with end mills (also known as end mills and square-shouldered milling cutters), while through grooves are mostly machined with three-face flute milling cutters, and, of course, through grooves can be machined with end mills as well.

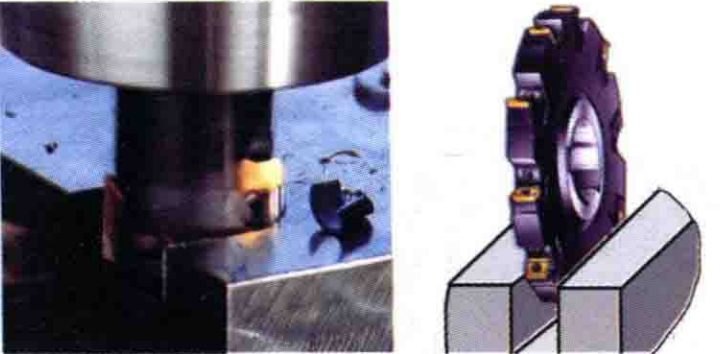

3、 milling steps

Step milling is to use the circumferential edge and end edge of the milling cutter at the same time to process steps on one or both sides of the workpiece (see Figure 1-3). Step milling is generally done with an end mill (also called an end mill or a square shoulder mill), or a double-sided milling cutter (cylindrical cutting edge and one side of the cutting edge). Of course, an end mill can also be used for the slot. to process.

4、milling T-slot

Milling T-slot as shown

5、milling narrow slots and cut off

Milling narrow slots and cut off as shown in Figure 1-4

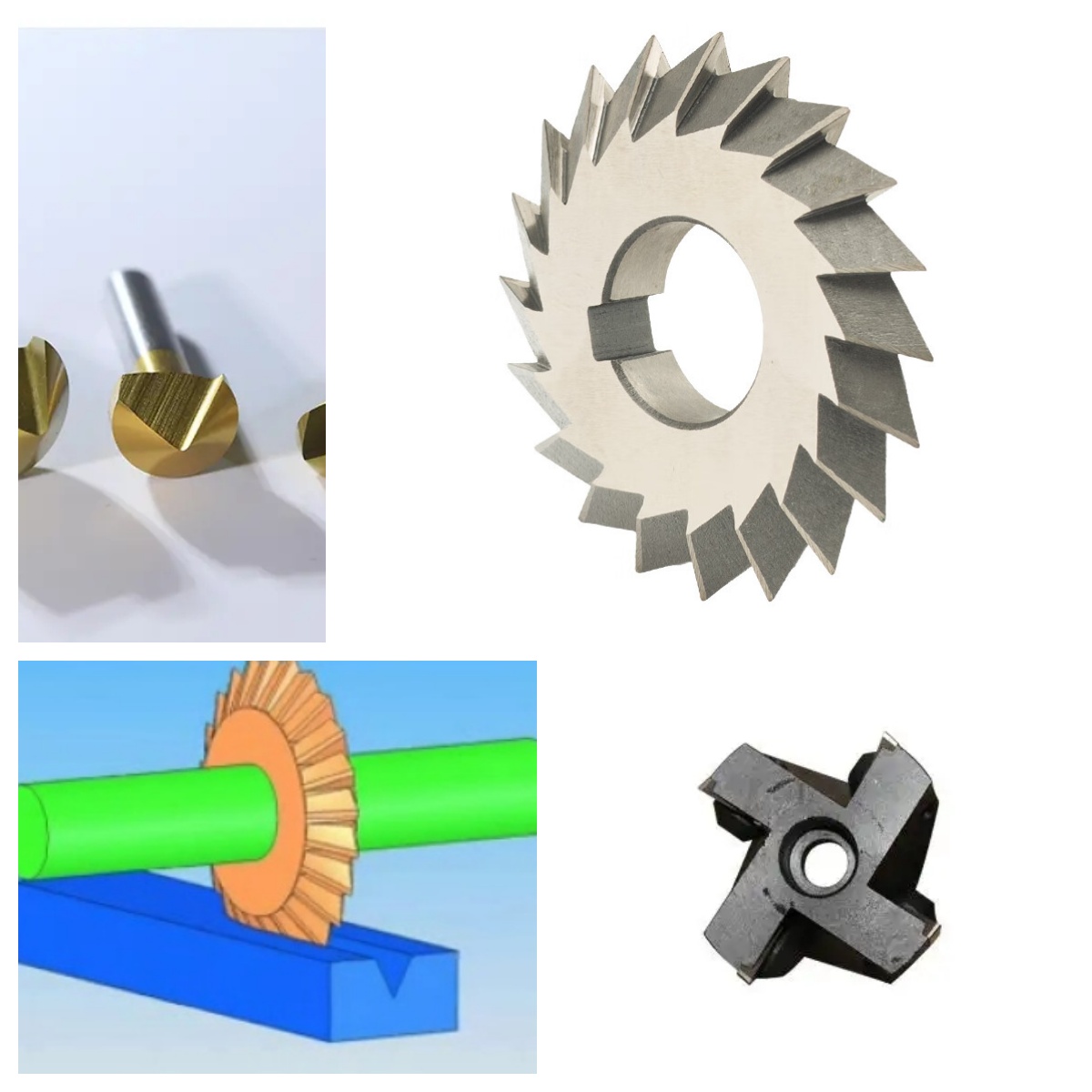

6、 milling angle

Milling angle refers to milling the workpiece with a specific angle of the milling cutter to form a specific side or both sides of the bevelled surface, Figure 1-5 shows a variety of angles of the milling cutter.

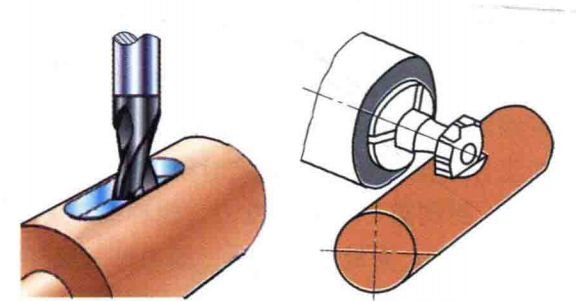

7、milling keyway

Milling a keyway is the milling of a closed keyway for a flat or half-round key on a shaft. These keyways generally have high requirements in width, and the slot is closed. Keyway milling cutter shown in Figure 1-6

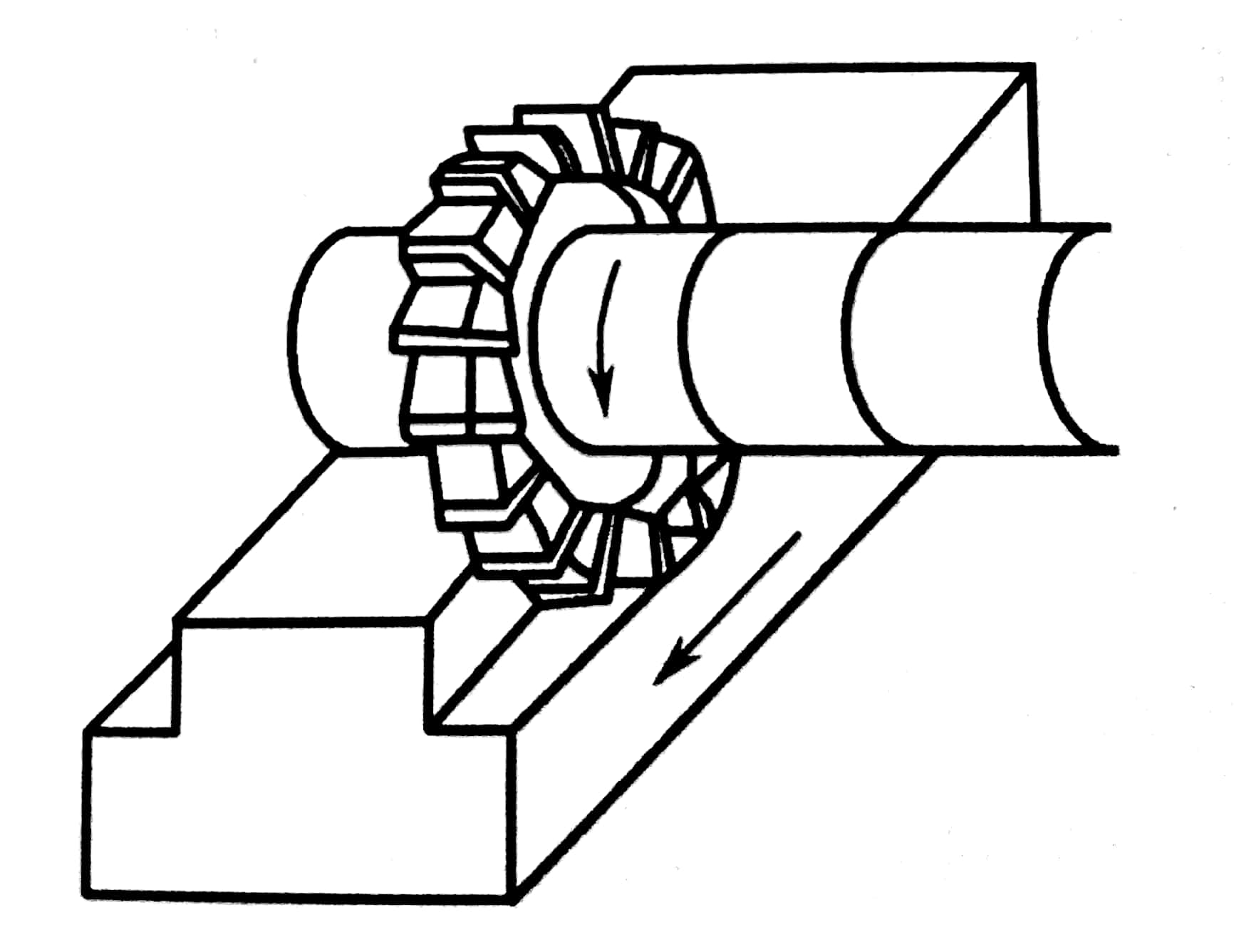

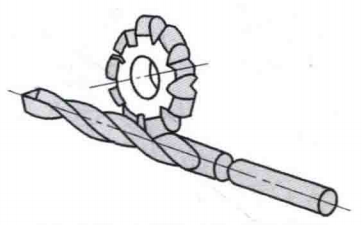

8、milling tooth shape

Milling tooth shape is to cut out the tooth shape of gear or rack by forming method or Fan Cheng method. Gear hob and gear milling cutter shown in Figure 1-7.

9、 milling spiral groove

Milling spiral groove is milling a spiral groove on the workpiece, typically as shown in Figure 1-8 twist drill groove milling.

10、milling surface

Milling a surface is a two-dimensional action with a milling cutter, machining a surface with the circumferential flute of a milling cutter such as an end mill, as shown in Figure 1-9for an end mill.

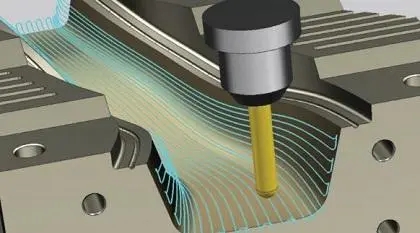

11、milling three-dimensional surface

Milling three-dimensional surface refers to the milling cutter to do three-dimensional movement, so as to process the complex shape of the three-dimensional surface, such as shown in Figure 1-10 for the rounded corner milling cutter.